ProX Carbon Rim QC And Testing

Quality Control and Testing are important procedures before ProX carbon rims brought to market.

Before launching, each new product will be tested for quality to guarantee durability and strength. After mass production, samples will also be tested randomly from each batch to ensure quality consistency. The main tests includes:

Quality Control starts from top-level design, and is implemented in every process of production.

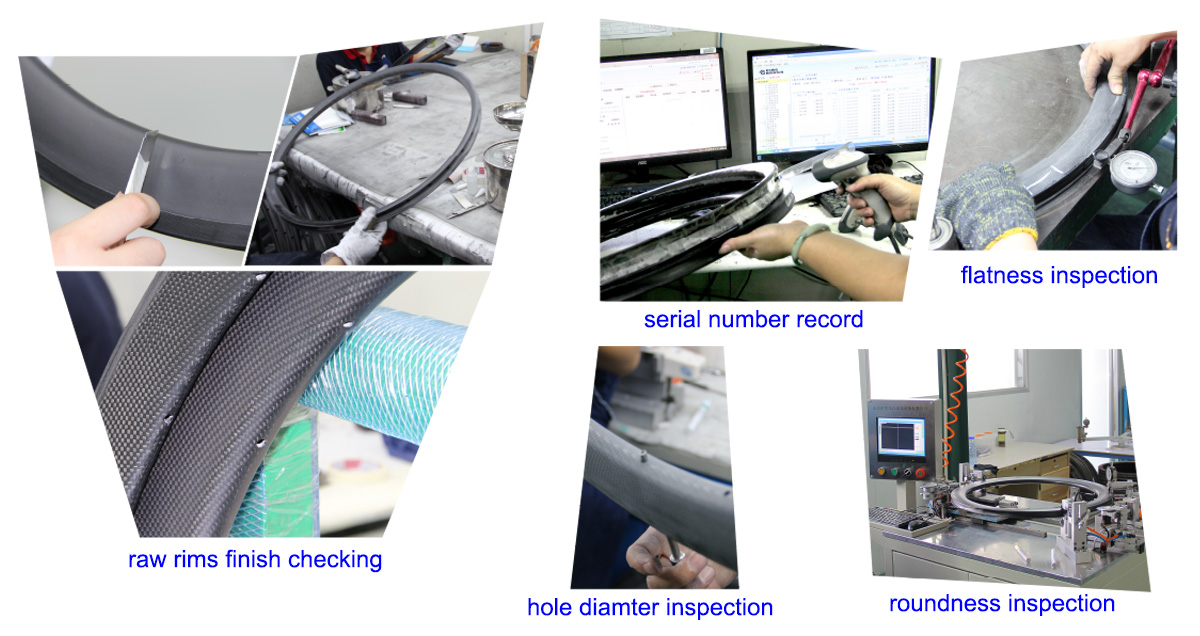

The main QC process includes:

Mold Check

Before every batch of production started, mold condition is checked, make sure the main body and lock of molds are in good condition and cleaness.

After every batch of production finished, mold is cleaned, and put in specific shelf which indicated the mold number.

Mold number indicates whether it belong to Road or MTB rim mold, as well as the height and width of rim.

Dimension Check

After each procedure finished, there will be dimension checking before it is moved to next procedure.

Such dimension checking includes rim width, height, flatness, roundness, diameter of valve hole and spoke holes, hole distance, etc.

Besides, the rim finish is checked, make sure there is no wrinkle or bubble.